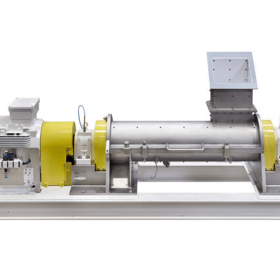

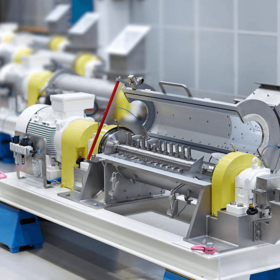

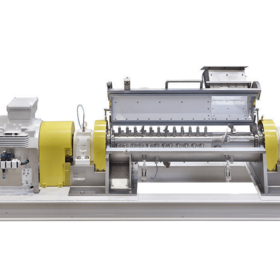

Lödige's Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

Machine type

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances.

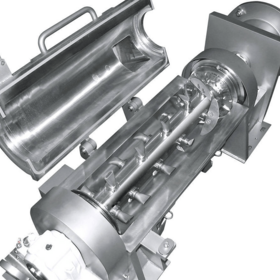

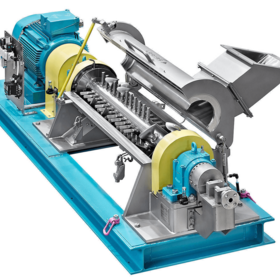

The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The resulting centrifugal force forms a concentric ringlayer of product along the drum wall. The product is moved through the mixing chamber in a plug-flow manner. The retention time depends on the filling level, speed, geometry and mixing tool adjustment as well as the throughputs but is extremely short compared with a continuous Ploughshare Mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. The friction of the product is increased through the high speed of the mixing tools but is still gentle enough due to the short residence time during the process.

Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray. In this way, large liquid quantities can be easily added and mixed.

A product is automatically granulated due to the bridging effect when liquids are added to products which turn sticky in contact with a liquid or if they contain binding agents. This granulation effect can be more or less pronounced. Usually the bulk density of the product is increased as soon as it is subsequently dried. In most cases, the resulting grain size is between 100 µ and 1.5 mm. In a certain extent, it can be controlled by adjusting the liquid quantity and the process parameters.

The coating of particles with, for example, molten fat, is performed effectively using a ring layer mixer. The cooling and recrystallization has to be done in downstream equipment.

Mixing, dispersion, breaking up, moistening, glue application, paste preparation, compaction, granulation, agglomeration, remixing.

- ATEX conformity according to 2014/34/EU directive

- Selection of materials in contact with the product

- Mixing drum lining as wear, corrosion and anti-adhesion protection

- Application-specific use of mixing elements

- Liquid addition via hollow shaft or injectors tangentially from the outside

- Temperature control jacket

- Wear protection of mixing elements

Ringlayer mixer CoriMix® for continuous operation

Certificates & approvals

When fulfilling your requirements, we leave nothing to chance!

We are regularly certified by recognized German and international testing centers.