Lödige as a partner for the

cosmetics industry

In safety, purity and reproducibility, the production of cosmetic products is often very similar to the production of pharmaceuticals. In this context, our specific processing know-how for mixing, drying, granulation and dispersion forms the basis of our innovative system solutions for the cosmetics industry. Customer-oriented design of machines and machine lines is as much part of our services as the development of extensive cleaning systems.

Process reliability and strict adherence to current standards in hygiene are equally important to the design of our machines.

The Lödige test centre provides various solutions for your experiments for process development and achieving a reliable scale-up to machines at a production scale.

Process engineering solutions

Through a wide range of process engineering systems and machines, Lödige provides a product-specific process design, which can fully implement your requirements.

Machines for the cosmetics industry

Lödige provides various mixing, granulation, drying and dispersion machines for the different process engineering based production steps of cosmetics.

Mixing granulator (Laboratory machine)

Laboratory mixing granulator with exchangeable vessel Mixing, granulation and temperature control in one machine Exchangeable vessels with a volume of 1, 5, 10 or 15 l GMP-compliant design User-friendly, integrated control system Operation-ready system

Ploughshare® Mixer (Laboratory machine)

Guaranteed Lödige quality Attractive value for money Functional design Ideal for your product and process development Extensive range of accessories

Ploughshare® Mixers for batch operation "Hygienic Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Extremely high mixing quality Short mixing times Reproducibility of batches Gentle product treatment High availability Low-maintenance mixer concept Easy accessibility of all internal mixer components Multi-stage processes in one machine

Ringlayer mixer CoriMix® for continuous operation

Compact machine unit with high throughput Extremely high mixing homogeneity Versatile application options Easy operation and cleaning High operating reliability and service life

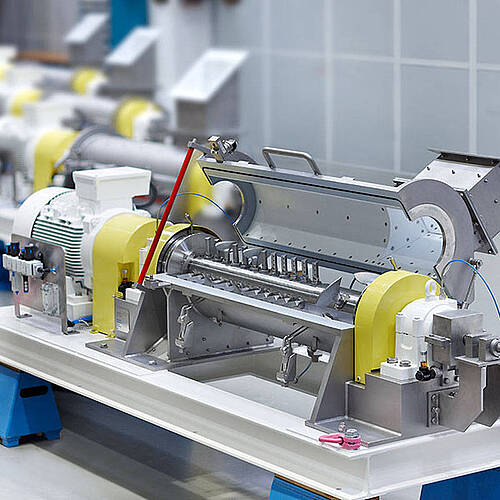

The mixing granulator

Mixing granulator for pharmaceutical products, cosmetics and food GMP-compliant design Modular WIP system for the machine and all additional components Automatic liquid addition in different versions New pharmaceutical controls Temperature control jacket for heating/cooling Integrated sieve on machine outlet Vacuum feeder Customised ATEX concepts

Vacuum shovel dryer DRUVATHERM®

Intense mixing prevents temperature and moisture gradients within the product Maximum heat transfer coefficients ensure excellent dryer performance Gentle thermal product treatment in vacuum mode Multi-phase process (mixing, granulation, drying, cooling) Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

Reliable scale-up Production development under consideration of industrial factors “All-in-one process” (mixing, granulation, drying, cooling) Intense mixing prevents temperature and moisture gradients within the product Short drying times through intense product movement and effective application of thermal energy Gentle thermal treatment at low temperatures using a strong vacuum Cost-efficient solvent recovery

Applications for the cosmetics industry

In the past decades, Lödige has become an established partner for process machines and equipment in the cosmetics industry. Global corporations for facial and body cosmetics rely on our machine engineering solutions just like large brands and smaller manufacturers of hair cosmetics, hand lotions or bath essences.

The range of Lödige machines goes far beyond the well-established horizontal and vertical mixing systems.

Downloads

System Solutions for the Cosmetic Industry