The production of cosmetic powder products requires fast, homogeneous mixing of different components that vary significantly in quantity. With Ploughshare® Mixers designed by Lödige Process Technology, all the stages of the mixing process can take place in one machine, which means that these mixers represent a very efficient solution to this complex process engineering task.

Loose and pressed cosmetic powder products are made up of several ingredients in different ratios. For example, tiny amounts of pigments have to be mixed with large quantities of carrier material. Every stage of the production of these powder products is highly complex. Firstly, the individual components have to be mixed quickly and evenly. Next the pigments need to be dissolved without causing streaking. The third step involves adding precise amounts of liquid binding agent and distributing it without flocking to ensure high-quality pressing results. This phase may also include carefully mixing in effect pigments. As a result, highly sensitive and expensive additives, such as mica (CI 77019), have to be processed without causing damage or leading to a deterioration in quality. Another problem is that the temperature of the materials must not exceed a critical level during mixing to ensure that the product does not change colour.

Using the Ploughshare® Mixer

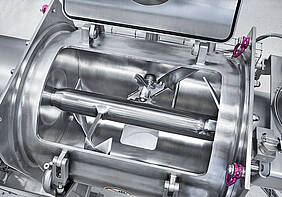

In many cases the use of horizontal Ploughshare® Mixers has proved to be the ideal solution to these varied and complex requirements. These mixers operate based on the mechanically generated fluid bed principle developed by Lödige, which ensures a high energy input and produces excellent mixing results. In addition, the mixers make it possible for all the stages of the cosmetic powder production process to take place in one machine. This results in short process times and a high level of flexibility. Liquids and other additives can be introduced via a single-substance nozzle in the venting port. The small models in particular, which have a gross volume of 130 or 300 litres, offer the high levels of flexibility needed by manufacturing companies which have small batch sizes and formulations that change frequently. A cooling jacket with a large heat transfer area allows for effective temperature control. The distance between the mixing elements and the wall has been kept to a minimum. By machining the drum, distances of 0.5 to 1.0 mm can be achieved. The result is that only a very small amount of the product remains in the drum after it is emptied, even in the case of highly adhesive materials.

Patented mixing principle

The central feature of the mixer is a special arrangement of Ploughshare® shovels on a horizontal shaft. The shovels rotate in a cylindrical mixing vessel, which is positioned horizontally. The size, number, position, shape and circumferential speed of the shovels are carefully coordinated to create a three-dimensional movement in the materials during the mixing process. This means that the materials are continuously mixed by the mixing tools to prevent dead spots or areas of low movement and to guarantee a quick, precise and reproduceable mixing process. The special design of the mixing tools ensures that the mixture is removed from the drum wall in a radial movement to prevent particles becoming stuck between the wall and the mixing tools. The mechanically generated fluid bed principle causes no damage to the product and is ideal for delicate, heat-sensitive substances. Modified shovels are available for special requirements and material properties. These produce the best possible results even when processing the most sensitive products. In some mixing tasks, in particular dissolving pigments and distributing liquid binding agent, the mixing elements need additional support. For this purpose, serrated choppers can be installed. These have a separate drive system and rotate at high speed. They help with the distribution of substances within the product. The resulting short mixing time together with the efficient use of drive power keeps the energy consumption to a minimum. In addition, a complex two-substance nozzle is not required.